In the Architecture, Engineering, Construction, and Owner-Operator (AECOO) industries, we often hear the phrase "you have to spend money to make money." But rarely is this principle more clearly demonstrated than in the adoption of terrestrial laser scanning technology. While the upfront costs of implementing 3D laser scanning can seem substantial to project managers and decision-makers, the long-term financial benefits create a compelling return on investment that transforms how we think about project economics.

At Spatial Reality Solutions (SRS), we've witnessed this transformation firsthand across various projects. What we've learned is that the initial investment in precision technology doesn't just pay for itself—it fundamentally changes the cost structure of entire projects, often saving multiples of the original scanning investment while delivering value that extends far beyond the immediate project scope.

When Two Approaches Collide: A Tale of Efficiency

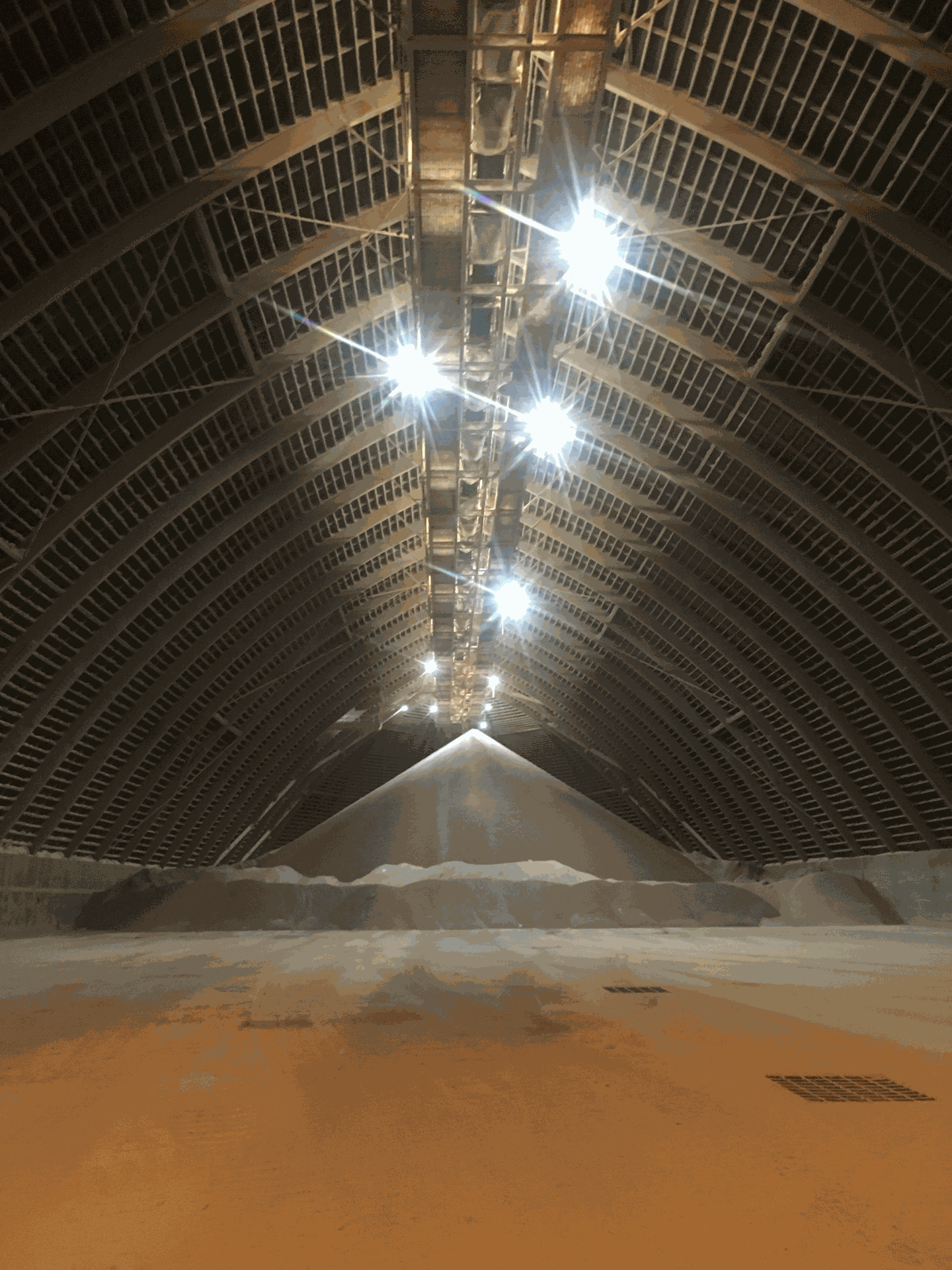

On an industrial facility, deploying terrestrial laser scanning equipment for what seemed like a routine as-built project revealed a perfect case study in how different approaches to data collection can dramatically impact project outcomes, costs, and safety.

As the SRS team was setting up equipment, they encountered a traditional survey crew on-site. After striking up a conversation, they learned the surveyors were tasked with an as-built for a small portion of the facility using RTK-GNSS technology. The project seemed straightforward enough: the client needed to route a new pipe from one area to another, requiring updated documentation of the existing infrastructure.

as-built for a small portion of the facility using RTK-GNSS technology. The project seemed straightforward enough: the client needed to route a new pipe from one area to another, requiring updated documentation of the existing infrastructure.

The surveyors were facing several immediate challenges that anyone in the geomatics industry would recognize. First, RTK-GNSS technology struggles in industrial environments filled with metal buildings due to multipath interference—signals bouncing off structures can compromise accuracy. Second, the complex nature of industrial sites means that traditional feature codes and point-based data collection, when later transposed to CAD, often introduce errors that compound throughout the design process. Third, their planned deliverable—a PDF plan at 1:500 scale with a coordinate table—would provide only a limited picture of the site's complexity.

But the most striking limitation was scope. They were capturing data for just a small portion of the facility, leaving the rest of the site undocumented despite the interconnected nature of industrial infrastructure.

While the survey crew worked, the SRS team also encountered the six engineers who had commissioned their work. These professionals had traveled between 300 and 600 kilometers to reach the site, armed with clipboards, digital cameras, and notepads. Due to their extended travel times, they had only a short window to capture photographs, measure pipe diameters, take notes, and return to their offices.

The Power of Comprehensive Capture

In the same timeframe that the survey crew struggled to document their limited area with RTK technology, the SRS team set control points with a robotic total station and systematically scanned the entire exterior of the facility. Everything—buildings, overhead conduit trays and racks, pipes, support piles, flanges, valves, and access points—was captured with millimeter-level accuracy.

captured with millimeter-level accuracy.

Beyond the geometric data, the team collected 360-degree HDR panoramic imagery throughout the site, creating a comprehensive visual record that would prove invaluable. The entire data acquisition was completed while the survey crew was still working on their small section.

Back in our office, the data processing took two days. The result was a complete digital twin of the facility, accessible through a secure web-based portal that allowed stakeholders to measure distances, view high-resolution imagery, assign tasks to team members, and even import Building Information Models (BIM) like Revit files—all from any computer with internet access.

When the results were presented to the engineer and other stakeholders, something remarkable happened. That single acquisition had created a snapshot in time of the entire facility that could be accessed by engineers, contractors, subcontractors, and other project team members indefinitely. The data became a single source of truth for the project, eliminating guesswork and reducing the need for multiple site visits.

The Unexpected Return Call

After delivering the 3D scan data, SRS received a phone call from the surveyor at the industrial site. His crew was still struggling to piece together the traditional survey data they had collected and compile it into usable CAD drawings. They were facing challenges interpreting their field notes and connecting the relationships between various infrastructure elements.

With the client's permission, SRS invited the surveyors to access the web portal. Within minutes of walking them through the 3D data, they experienced what could be called the "aha moment." The panoramic imagery held the visual context they needed to understand the spatial relationships that their point-based data couldn't convey. In less than five minutes, problems they'd been wrestling with for an extended period suddenly became clear.

This wasn't just a technical victory; it was a demonstration of how comprehensive data capture creates value that ripples outward, often in unexpected ways.

The Multiplication Effect: Understanding True ROI

Let's examine the financial implications of this real-world scenario. The traditional approach involved:

- Two survey crew members working multiple days on-site

- Six engineers traveling 300-600 kilometers each

- Vehicle costs, accommodation, and per diems for the engineering team

- Limited data capture requiring potential return visits

- Extended office time struggling to interpret and compile field data

- Safety exposure for eight people in an industrial environment

In contrast, the laser scanning approach delivered:

- Comprehensive facility documentation in the same timeframe

- Immediate accessibility for all stakeholders via web portal

- Elimination of travel costs for the engineering team (they could have "visited" the site virtually)

- Reduced safety risk with fewer people in potentially hazardous areas

- Complete visual and geometric context preventing interpretation errors

- Reusable data for future projects and facility management

The Architect's Advantage: Beyond Initial Design

For architects, the value proposition extends far beyond initial documentation. Consider a heritage building renovation where mechanical, electrical, and plumbing (MEP) systems must be integrated into existing structures. Traditional measurement approaches often require multiple site visits by different trades and consultants, each working with incomplete information.

systems must be integrated into existing structures. Traditional measurement approaches often require multiple site visits by different trades and consultants, each working with incomplete information.

Terrestrial laser scanning creates a comprehensive foundation that serves every discipline throughout the project lifecycle:

Design Phase Benefits:

- Architects can design with confidence, knowing exact spatial constraints

- MEP engineers can route systems with full knowledge of existing conditions

- Structural engineers can assess load paths and connection points accurately

- All disciplines work from the same precise base data, reducing coordination conflicts

Construction Phase Benefits:

- Contractors can pre-fabricate components off-site using accurate measurements

- Clash detection between new and existing systems happens in the digital realm, not on-site

- Construction managers can track progress against the as-built baseline

- Change orders are minimized because surprises are eliminated

Operations Phase Benefits:

- Facility managers have complete documentation for maintenance planning

- Future renovations start with comprehensive existing conditions data

- Building performance can be analyzed against actual, not assumed, conditions

- Asset management becomes data-driven rather than reactive

The Critical Foundation: Why Geomatics Expertise Matters

While terrestrial laser scanning technology has become more accessible, successful implementation requires far more than simply operating a scanner. The foundation of any reliable scan project lies in proper control surveys and geomatics expertise that ensures data accuracy, reliability, and usability throughout the project lifecycle.

At the industrial facility, the SRS team's first step was establishing control points using a robotic total station. This fundamental geomatics practice creates the spatial framework that allows scan data to be integrated with existing survey information, engineering drawings, and future project phases. Without proper control, even the most sophisticated scanner produces data that cannot be reliably referenced to real-world coordinates.

At the industrial facility, the SRS team's first step was establishing control points using a robotic total station. This fundamental geomatics practice creates the spatial framework that allows scan data to be integrated with existing survey information, engineering drawings, and future project phases. Without proper control, even the most sophisticated scanner produces data that cannot be reliably referenced to real-world coordinates.

The difference becomes critical when architects need to integrate scan data with existing CAD drawings, when engineers must connect new systems to documented infrastructure, or when contractors require precise positioning for fabrication and installation. Improperly controlled scan data can introduce systematic errors that compound throughout the project, potentially costing far more than the original scanning investment.

SRS brings nearly two decades of surveying and mapping expertise to every laser scanning project. This geomatics foundation ensures that scan data integrates seamlessly with traditional survey methods, meets professional standards for accuracy and reliability, and provides the spatial reference framework that makes collaborative workflows possible. The technology is only as valuable as the expertise behind its implementation.

Conclusion: The SRS Advantage in Digital Transformation

What sets SRS apart is our holistic understanding of digital transformation within the AECOO industries. The industrial facility story demonstrates that these benefits often emerge in unexpected ways, creating value that extends far beyond the original project scope. Our team doesn't just capture data we create comprehensive digital ecosystems that serve entire project lifecycles. We understand that technology is most powerful when it connects people and communities, and our collaborative approach reflects this philosophy.

Whether you're an architect planning a heritage renovation, an engineer designing complex industrial systems, or a construction manager coordinating multi-disciplinary teams, SRS provides the precision, efficiency, and collaborative tools that transform project economics.

The question isn't whether comprehensive 3D documentation will become essential to your practice it's whether you'll partner with a team that understands how to maximize its value. Contact Spatial Reality Solutions to discover how our terrestrial laser scanning services can serve as your project's single source of truth, creating collaborative workflows that save time, reduce costs, and improve outcomes for all stakeholders.